Maintenance and servicing of CNC machines

Everything in one place - your SAVE-TECH service team

Do you expect more from service quality?

Then you've come to the right place. Our service team comprises mechanics, electrical technicians and software specialists.

SAVE-TECH's benchmark is professional service provision.

We can fix CNC machine tool malfunctions using the following systems:

SIEMENS, HEIDENHAIN, FANUC, and FAGOR

Service within 24 hours

Malfunctioning machine? Contact us and we’ll ensure your machine tool’s mechanical and electronic components operate reliably.

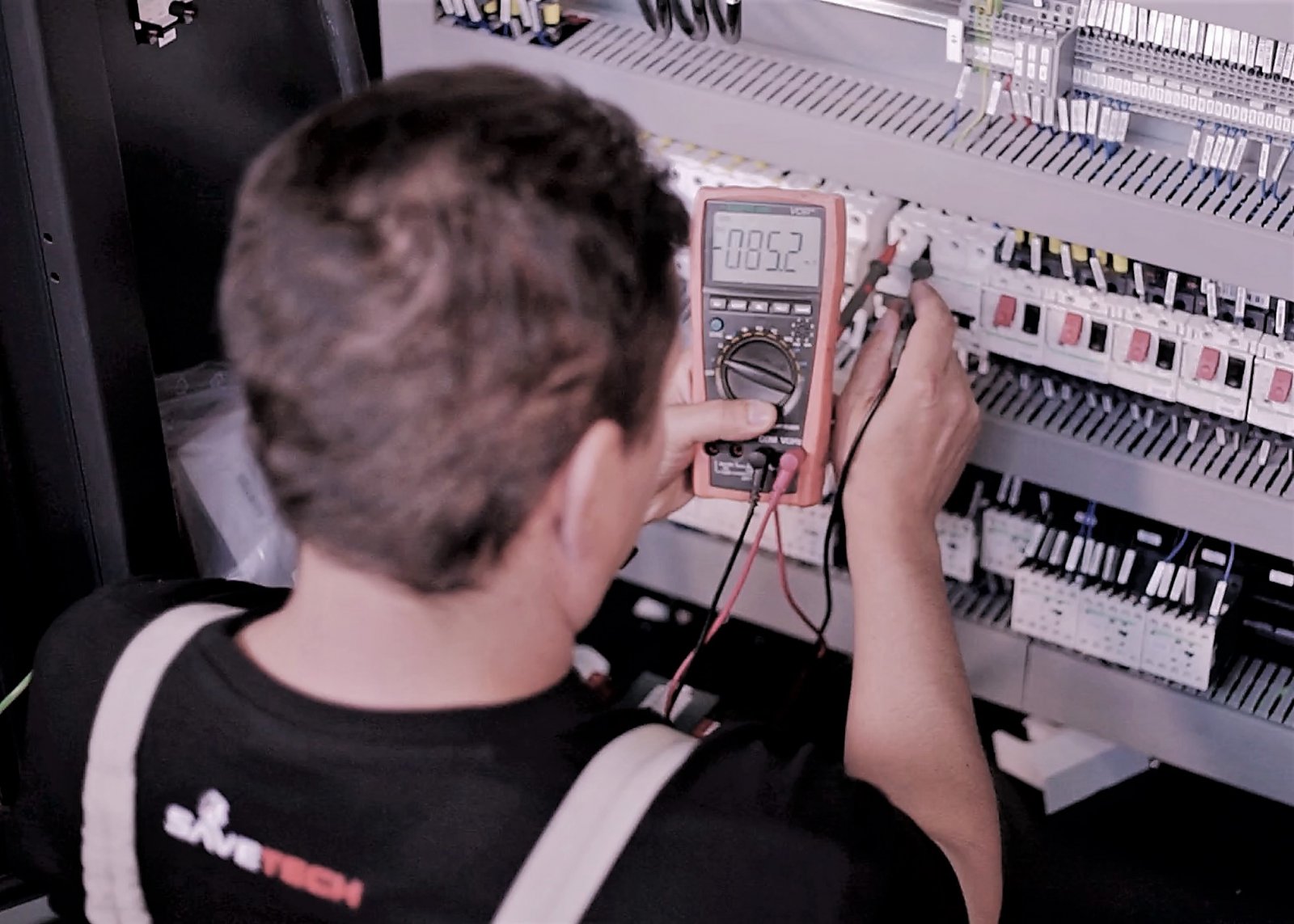

PLC diagnostics

Save time and money with the right diagnosis of machine tool malfunctions.

Repairs of SAUTER tool heads

Quality and responsibility come first

We provide precise repairs of by SAUTER Feinmechanik GmbH tool heads by collaborating directly with their plant in Germany. Tool head malfunction? We’re here to help. Visit our Trenčín service centre for our new express repair service within 24 hours when time is critical.

On-site services

We can fix most malfunctions at your site to get machine tools operating at their best.

Everything in one place

Assembly and disassembly on your machine tool, and replacement of damaged components. Complete functionality testing.

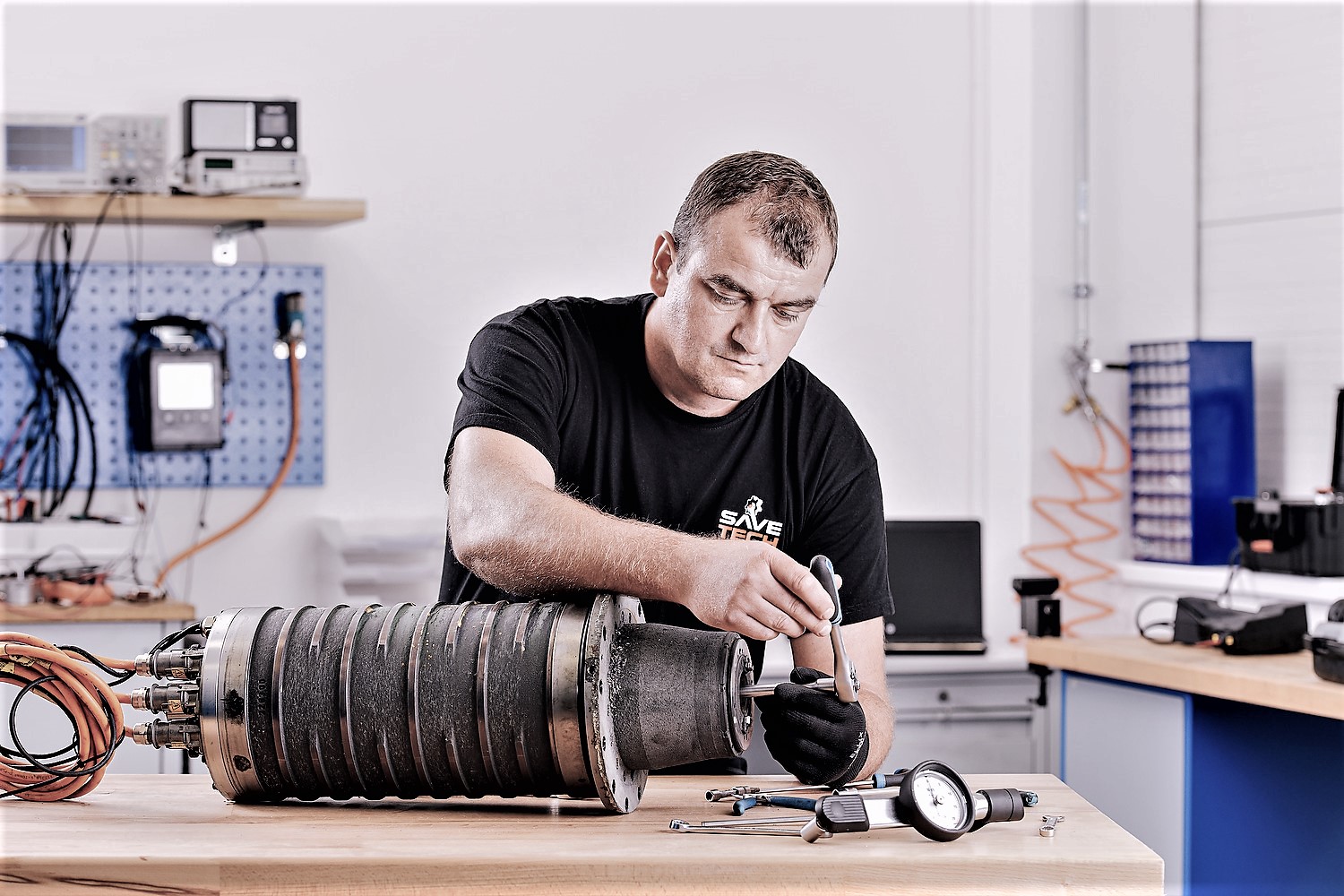

Spindle repairs and service

Our experts handle dozens of spindles every month. We ensure the precision and quality of our repairs. We combine complete servicing with diagnostics of your CNC equipment malfunction, disassembly, repair, and subsequent spindle installation with all the necessary software modifications. Spindle repair is a real challenge - it requires the right experience and latest resources. We use the latest CARL ZEISS technology for all measurement and accuracy control activities in spindle remanufacturing.

Precision of manufactured parts

Replacement parts' manufacturing precision is the cornerstone for durability and spindle clock cycles

- Machine tool spindle installation service

- Bearing replacement

- Manufacturing of new parts

- Grinding of individual parts

- Clamping packet adjustment